Propelling the project

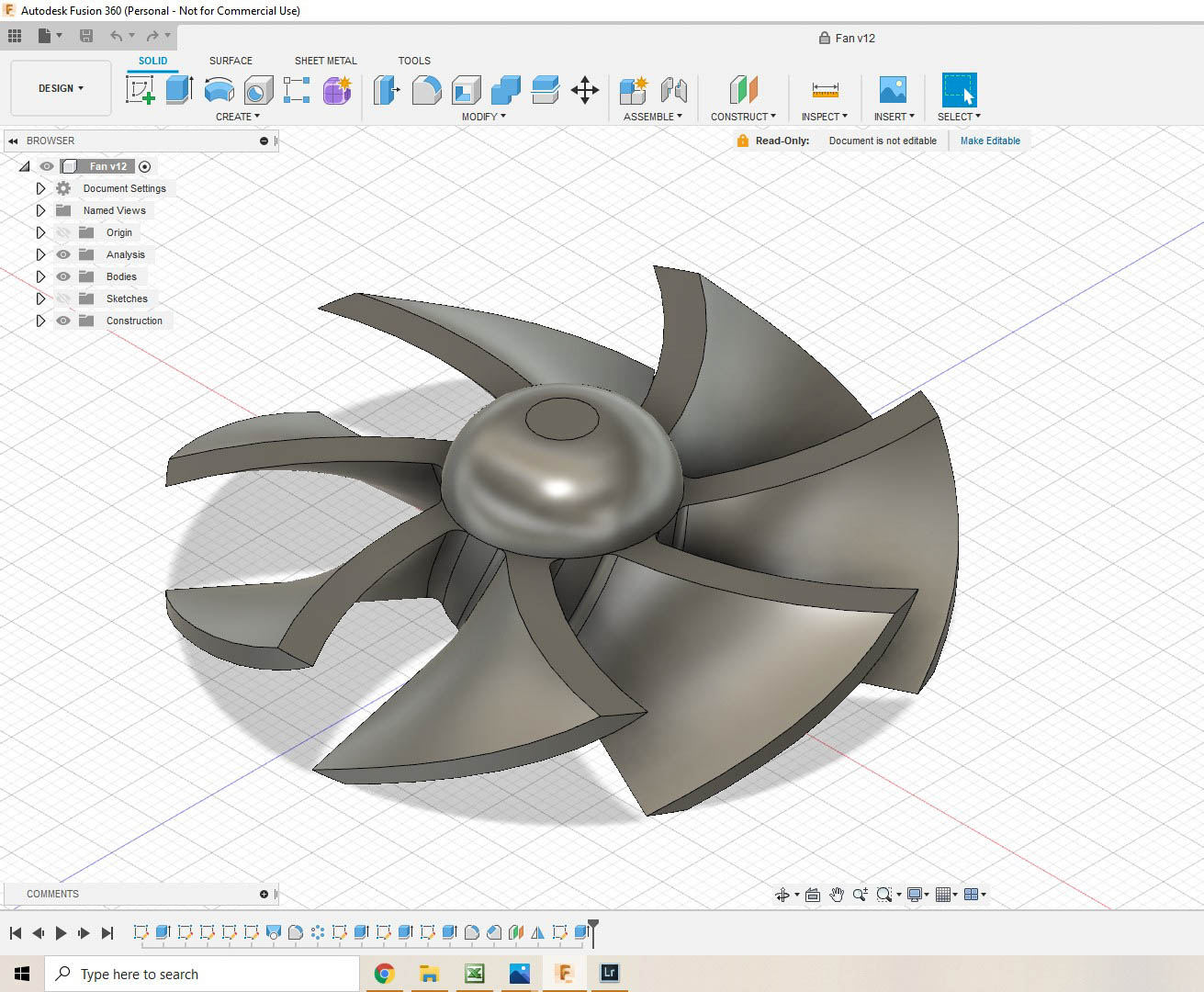

Next I needed a propeller. This was a perfect project for my 3D printer but first I needed to design it. I regularly use the computer CAD software Fusion 360 for designing various things in 3D although I must admit that I am far from being an expert.

It is actually quite exciting to be able to create various objects in three dimensions with just a few keystrokes on the computer keyboard.

For this propeller project, I was lucky: I was able to repurpose a fan design that I had done more than a year ago to repair my wife’s hair dryer. I remember spending a good part of an afternoon designing a new fan to replace the broken one. Since I had done a parametric design with Fusion 360 (defining the key dimensions not with fixed numbers but rather with variables), I was able, with just a few keystrokes, to reduce the original fan dimensions to the right scale for the propeller and adjust the hole diameter for the shaft to fit the miniature motor I had selected. I used white PLA on the printer and put a first coat of paint to match the color on Ava’s drawing. It turned out pretty good.