Looking for a boat

I really liked Simon’s idea of a vessel to collect waste material from the water surface using a paddle wheel with some screening material to filter out the water. My objective is to make a small animated model roughly 30cm long. Up front I could see that the biggest challenge would be with the hull of the vessel. The bow of the vessel needs to be somewhat open to house the paddle wheel. I surfed various web sites to see if I could get a toy boat to fit my needs but to no avail. I rapidly came to the conclusion that I need to fabricate the hull, as well as the other parts of the vessel with PLA plastic on my 3D printer.

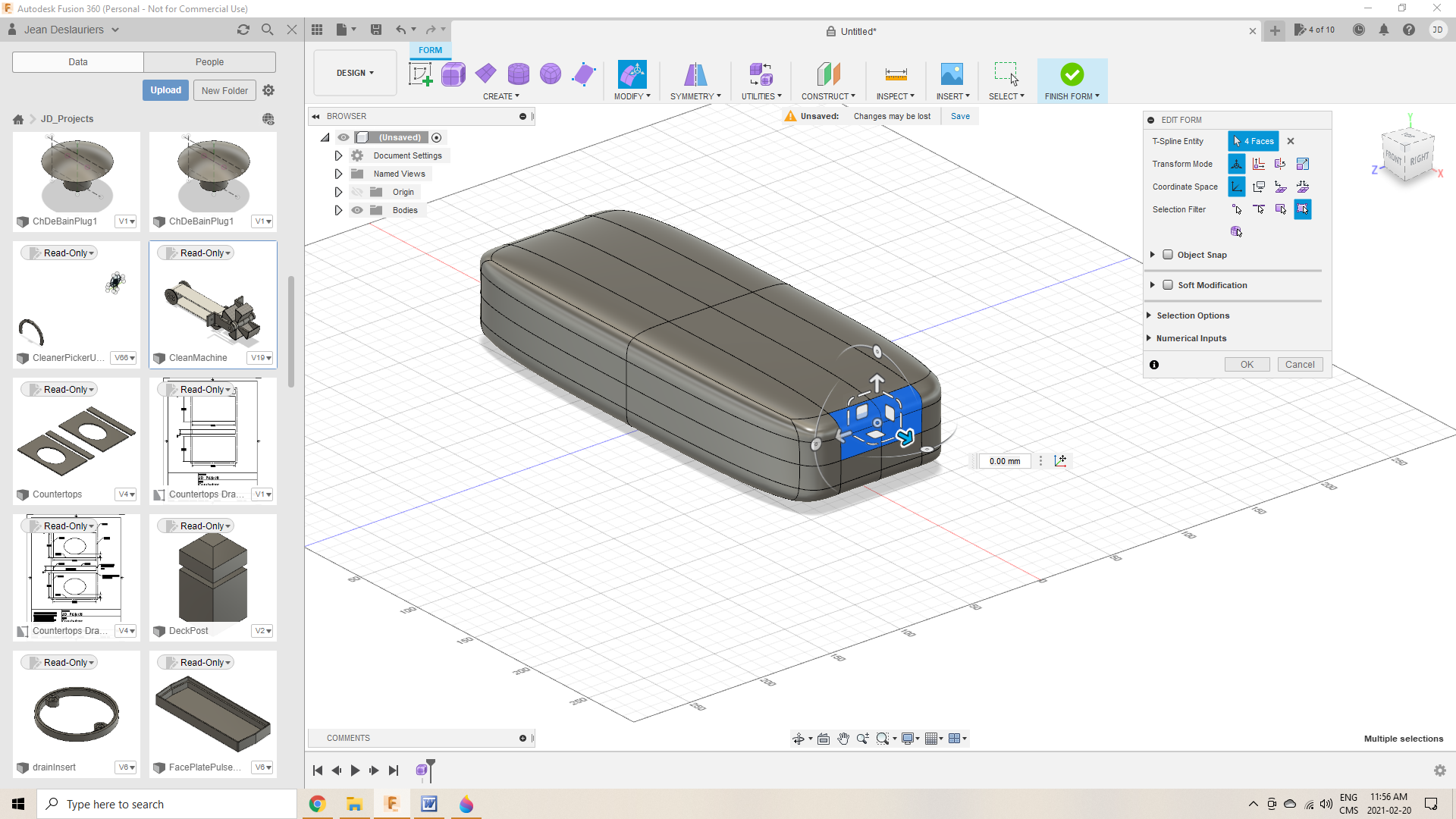

I use Fusion 360 for my 3D design needs but I am far from being an expert designer. The shape of a hull for a boat is very complex with curves of various kinds that are very difficult to parameterize (describe with xyz coordinates or angles).

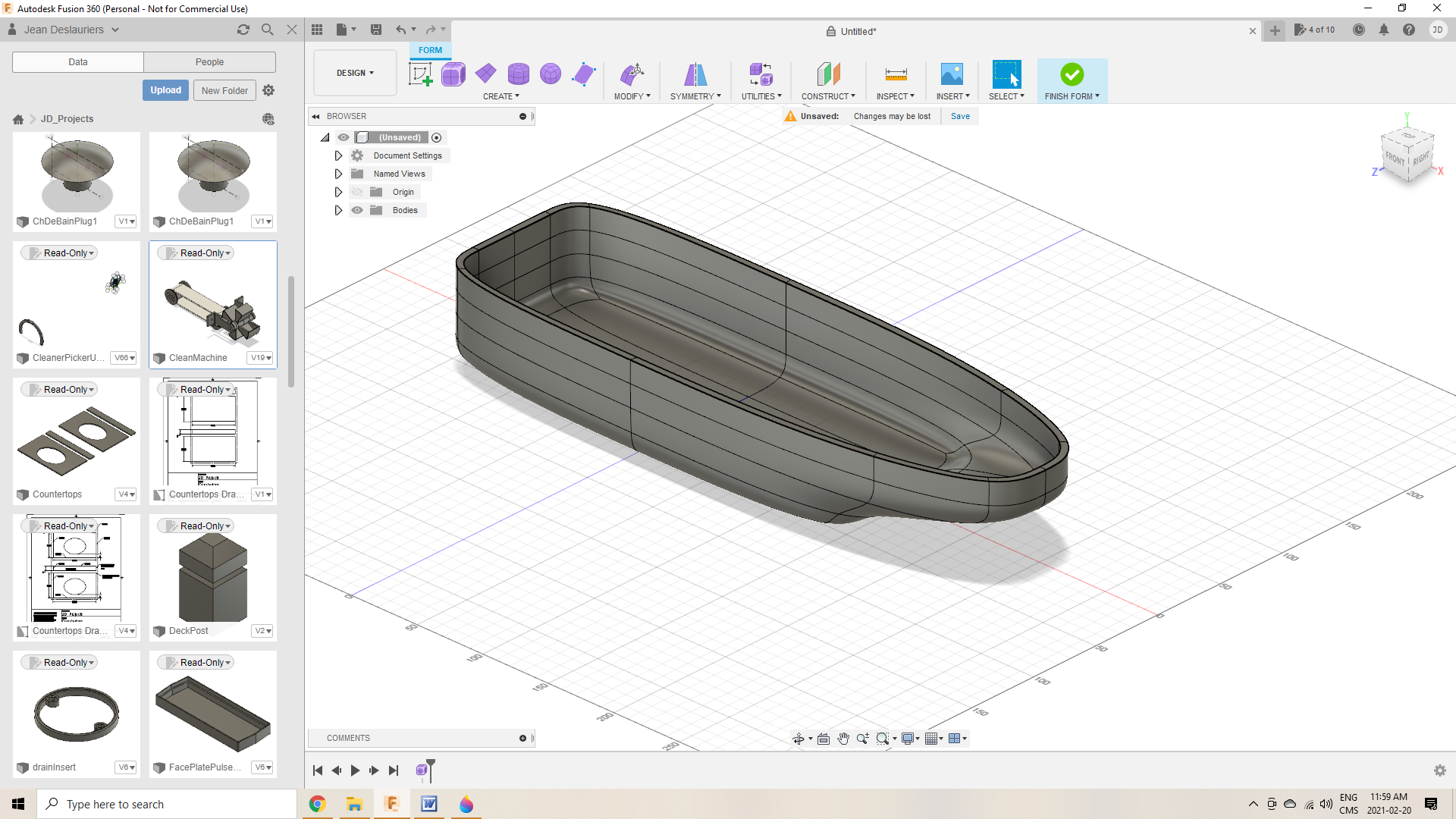

Therefore this invention from Simon forced me to develop a new skill in 3D design: sculpting. Luckily it is a function available on Fusion 360. So this week I watched a few YouTube videos and spent a couple of hours practicing before I started to master this exciting technique that will allow me to create artistic shapes that I could not produce otherwise.

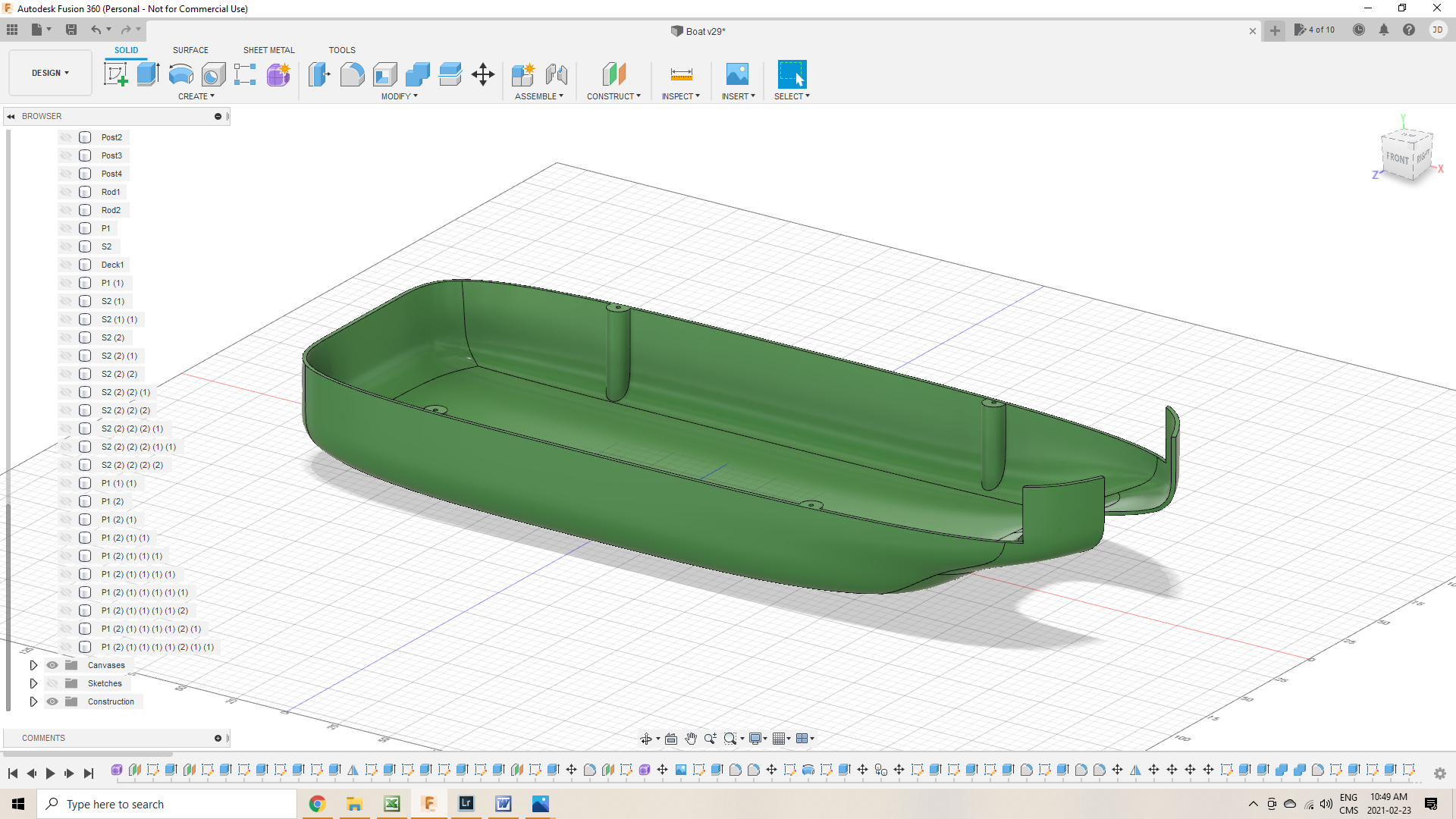

I was then able to design the exact hull I was looking for. Sculpting on the computer is very similar to sculpting with play doh. I first selected in the available menu of basic starting shapes a sort of elongated cube with rounded edges and asked for 64 cells or bricks (4 along the length, 4 over the width and the height). I then select with the mouse certain faces or edges and drag those in a given direction. Following a series of selections and dragging motions in various directions, followed by deletion of various surfaces and thickening of the resulting envelope I was able to create the very hull I was looking for.

Wow! Although things are still on paper (and in the computer memory), I feel that I have eliminated the biggest challenge.

I still have to fine-tune this hull to include anchors for the main deck and the things I want to install inside the ship. Once satisfied, I will also need to cut the final hull design in two pieces to allow the fabrication on my 3D printer.

Progress!!